Ukubetha kunye nokuFa ngenxa yokucinezelwa kwethebhulethi

Iimbonakalo

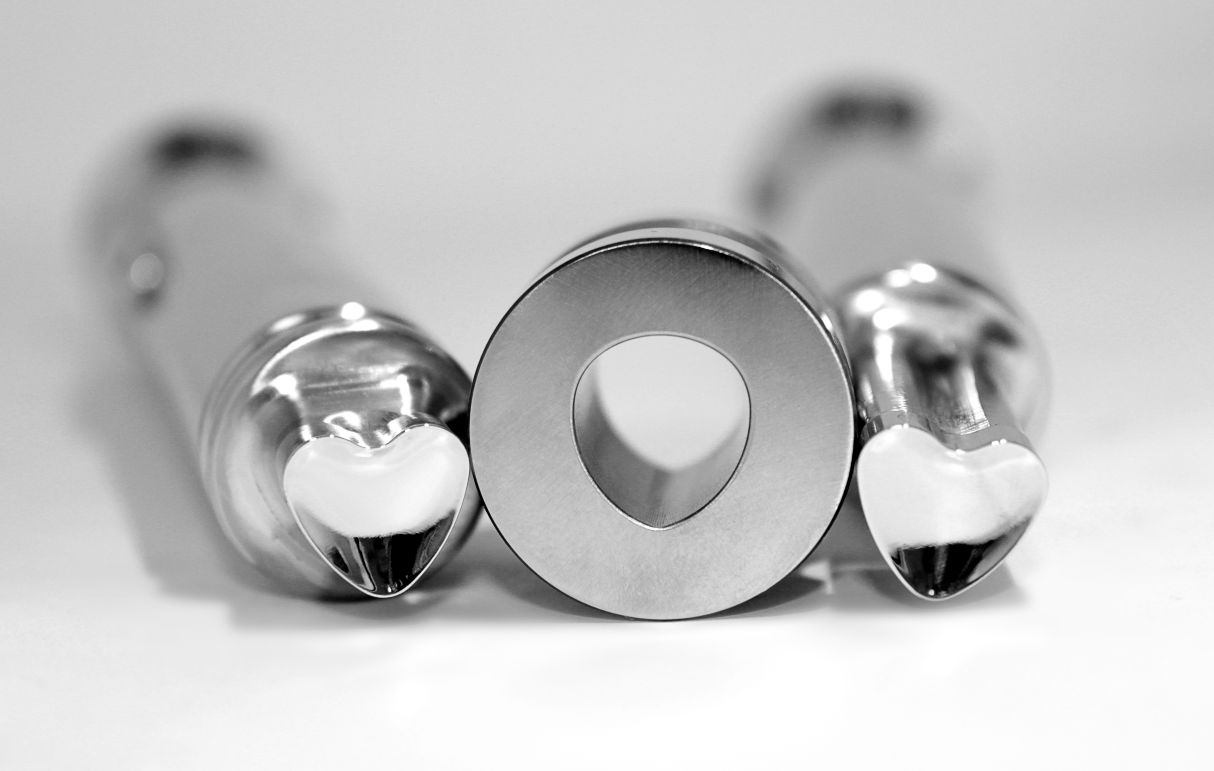

Njengenxalenye ebalulekileyo yomatshini wokushicilela iithebhulethi, i-tableting Tooling yenziwa ngokwethu kwaye umgangatho ulawulwa ngokungqongqo. Kwi-CNC CENTER, iqela lemveliso eliyila ngononophelo kwaye lenze i-tableting Tooling nganye.

Sinamava amaninzi okwenza zonke iintlobo zeebhondi kunye needayi ezifana nokwakheka okungqukuva nokukhethekileyo, i-concave enzulu, i-concave enzulu, i-bevel edged, i-de-tachable, i-single tipped, i-multi tipped kunye ne-hard chrome plating.

Asizamkeli nje iiodolo, kodwa sikwabonelela ngezisombululo ezipheleleyo zamalungiselelo aqinileyo ukunceda abathengi benze ukhetho olufanelekileyo.

Ngokusebenzisa uhlalutyo oluneenkcukacha lwe-odolo yangaphambili oluvela kwiqela lenkonzo yabathengi elinamava ukuze kuthintelwe iingxaki. Ngolawulo olungqongqo lwenkqubo yemveliso kunye nengxelo epheleleyo yokuhlolwa ukuqinisekisa ukuba zonke izixhobo ziyakwazi ukumelana novavanyo.

Ngokweemfuno zabathengi, asiboneleli nje kuphela ngee-punches and dies ezisemgangathweni, ezifana ne-EU kunye ne-TSM, kodwa sikwabonelela ngesixhobo esikhethekileyo sethebhulethi ukuze sikwazi ukufezekisa iimfuno zabathengi. Izixhobo ezahlukeneyo ze-punches and dies kunye ne-coating, ezinokufezekiswa kuphela ngamava eminyaka.

Izixhobo zokubhala iitablethi ezikumgangatho ophezulu zivumela umatshini wokushicilela iitablethi ukuba enze iintlobo ezahlukeneyo zeetablethi. Izixhobo ezahlukeneyo zokubhala iitablethi zikhulisa imveliso kwaye zinciphise ixesha lokuvelisa.

Ulondolozo

1. Emva kokuba imveliso igqityiwe, kufuneka kuhlolwe ngokupheleleyo iTooling;

2. Coca kwaye usule ngokupheleleyo isikhunta ukuqinisekisa ukucoceka kweTooling;

3. Coca inkunkuma kwi-Tooling ukuqinisekisa ukuba akukho oyile inkunkuma kwibhokisi yenkunkuma;

4. Ukuba igcinwe okwethutyana, yitshize ngeoyile yokulwa nomhlwa emva kokucoca uze uyibeke kwikhabhathi yeTooling;

5. Ukuba i-Tooling iza kubekwa ixesha elide, yicoce uze uyibeke kwibhokisi yesikhunta enedizili ezantsi.

Iindidi zemveliso

Iphephandaba lethu leveki

Yinyani ende eqinisekisiweyo ukuba umntu olungisa izinto uya kwaneliseka yi

into efundekayo kwiphepha xa ujonge.

-

I-imeyile

-

Ifowuni

-

I-Whatsapp

-

Phezulu